Cuir isteach aiseolas

Pengeluar Litium Silikat Cecair

Sileacáit litiam

Foirmle ceimiceach : Li 2 Si0 3 nó Li 2 onSiO 2

Príomhúsáidí :

Gloine speisialta agus criadóireacht : cosúil le gloine optúil agus gloine teas-resistant.

Breiseáin glaze ceirmeacha chun feidhmíocht a fheabhsú.

Ábhair ceallraí

Sciath frith-chreimeadh : foirmithe le púdar since agus bratuithe neamhorgánacha saibhir since eile, a úsáidtear chun meirge miotail a chosc (friotaíocht ardteochta, friotaíocht creimeadh).

Réimsí eile : iompróirí catalaíoch, breiseáin ábhair teasfhulangacha, etc

-

Réamhrá Déantúsaíocht na sileacáit photaisiam tá ról lárnach ag réitigh i dtionscail éagsúla cosúil le talmhaíocht, tógáil, agus innealtóireacht cheimiceach. Úsáidtear na réitigh seo, a dh...

BACA LAGI -

Réamhrá Le blianta beaga anuas, tá méadú tagtha ar an éileamh ar tháirgí ardfheidhmíochta uisce-repellant mar gheall ar an bhfócas méadaitheach ar mharthanacht agus ar chosaint i dtionscail éagsúla. Is ...

BACA LAGI -

Réamhrá Púdar sileacáit sóidiam , dá ngairtear gloine uisce nó gloine leachtach ina bhfoirm leachtach, is cumaisc an-versatile é le raon leathan iarratas ar fud na dtionscal iolrach. Tá an ...

BACA LAGI

What properties can Liquid Lithium Silicate improve as a ceramic glaze additive?

1. Reduce the melting temperature of ceramic glaze

During the firing process of ceramics, too high firing temperature will not only increase energy consumption, but may also cause problems such as ceramic deformation. After adding Liquid Lithium Silicate, the melting point of the glaze is reduced, allowing the ceramic to be fired at a relatively low temperature. This not only saves production costs, but also reduces the adverse effects caused by high-temperature firing and improves the yield rate. For example, in the production of some fine ceramic products, the use of glazes added with Liquid Lithium Silicate can better maintain the shape and details of the ceramics.

2. Enhance the hardness and wear resistance of ceramic glaze

In daily life and industrial applications, ceramic products need to have good wear resistance to extend their service life. Liquid Lithium Silicate reacts chemically with other components in the glaze to form a denser crystal structure, thereby greatly improving the hardness and wear resistance of the glaze. Whether it is ceramic tableware for daily use or ceramic tiles for architectural decoration, the durability can be improved by adding this additive.

3. Improve the gloss and transparency of ceramic glaze

Gloss and transparency are important indicators for measuring the beauty of ceramic glaze. Glazes with Liquid Lithium Silicate added can form a more uniform and smooth glaze after firing, making ceramic products present a crystal clear texture and bright luster. This is crucial for high-end ceramic artworks and decorative ceramics, and can greatly increase the added value of products.

4. Enhance the chemical corrosion resistance of ceramic glaze

Liquid Lithium Silicate also has good chemical stability and can enhance the chemical corrosion resistance of ceramic glaze. When faced with acid and alkali and other chemical erosion, ceramic glazes with this additive can better protect the ceramic matrix and extend the service life of ceramic products. This feature allows ceramic products to be widely used in industries such as chemicals and food that have high requirements for corrosion resistance.

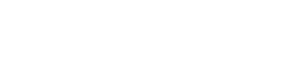

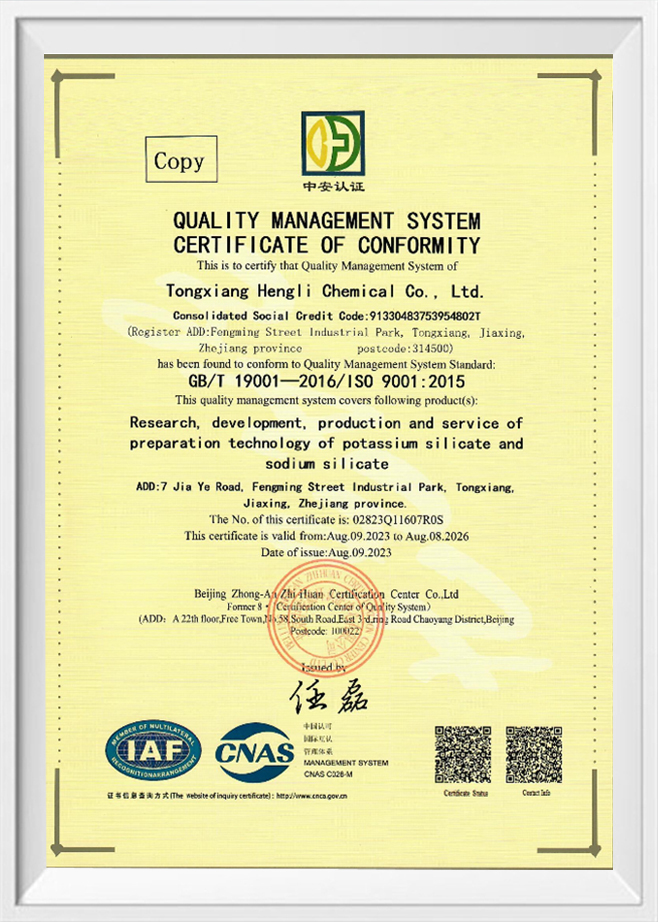

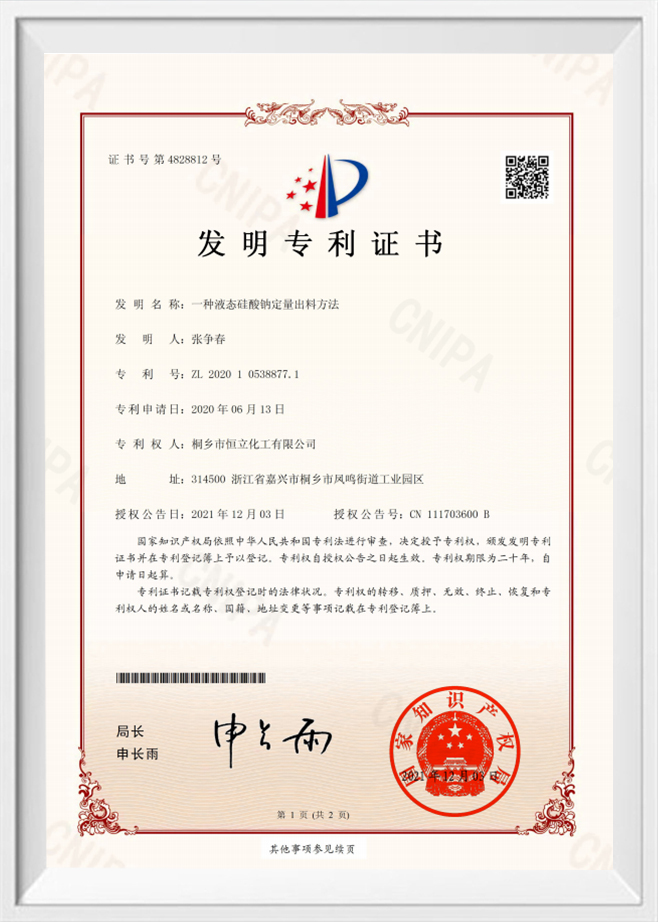

It is worth mentioning that professional inorganic silicon product manufacturers such as Tongxiang Hengli Chemical Co., Ltd. have rich experience and strong technical strength in the production of Liquid Lithium Silicate. Founded in 1997, the company focuses on the production of inorganic silicon products and has more than 30 products, covering a variety of silicate products including Liquid Lithium Silicate. With a strong technical team and rich production experience, Tongxiang Hengli Chemical Co., Ltd. has a unique understanding and control over the microstructure of colloidal silica and silicates, and is able to provide high-quality Liquid Lithium Silicate products for the ceramic industry to meet the needs of different customers.

As a ceramic glaze additive, Liquid Lithium Silicate has excellent performance in reducing melting temperature, enhancing hardness and wear resistance, improving gloss and transparency, and improving chemical corrosion resistance. With the continuous development of the ceramic industry, the requirements for glaze performance are getting higher and higher, and Liquid Lithium Silicate will surely play a greater role. The continuous innovation and development of companies such as Tongxiang Hengli Chemical Co., Ltd. will also provide better raw material support for the ceramic industry and promote the progress of the entire industry.